+86 151 277 20688

+86 151 277 20688

sales@hgffgroup.com

sales@hgffgroup.com

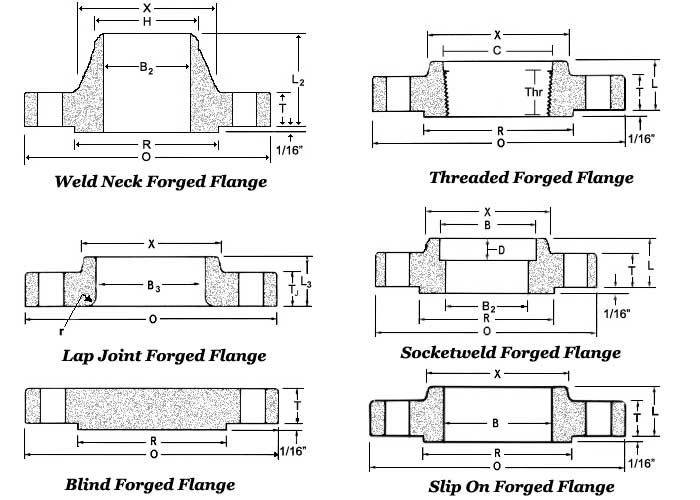

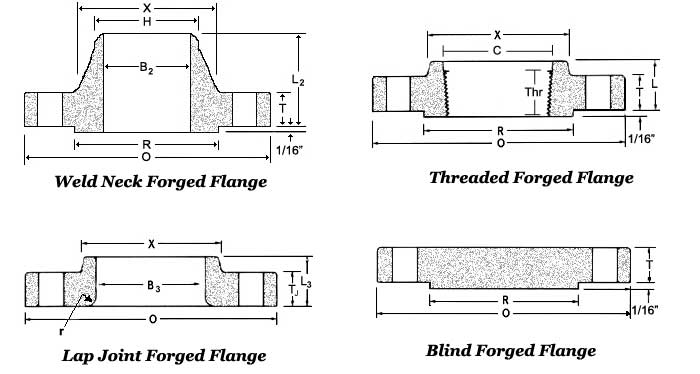

HGFF Group Co., Ltd. (HGFF) is an ISO manufacturer, Forged Flanges besides being their exporter to the Middle Eastern and European countries. A Stainless Steel Forged Flange can be defined as a metal disc, installed at the back of a tube, valve or any other object. It allows simple Fitting and replacement of a piping system. They undergo the forging process whereby mechanical, energy is applied to a steel flange, to change its shape when in a solid state. ANSI B16.5 Forged Flanges possess a better impact strength than Cast flanges and are stronger and reliable. We are suppliers of Titanium, Alloy Steel, Carbon Steel, Monel, Nickel, CuproNickel, Stainless Steel and Inconel Forged Flanges to the chemical units, Oil and refineries, shipbuilding, petrochemicals and gas processing and distribution centers.

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629,

DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Material & Grades of Forged Flanges :

Stainless Steel Forged Flanges :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Forged Flanges :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel Forged Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel Forged Flanges : ASTM A350, LF2, LF3

Alloy Steel Forged Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel Forged Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500

(Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy Forged Flanges :

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS

No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel

600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No.

N10276), Alloy 20 (UNS No. N08020)

| Forged Flange | Forged Steel Flanges |

| ANSI B16.5 Forged Flanges | Forged Flange Dimensions |

| ASME B16.5 Forged Flanges | ANSI B16.5 Class 150 Forged Flanges |

| Stainless Steel Forged Flanges | Suppliers SS Forged Flange |

| Forged Plate Flanges Dealer | ASME B16.47 Series A and B Forged Flanges Exporter |

| ANSI B16.5 class 150 Forged Flange Stockholder | ANSI 150 Forged Flange Distributors |

| Carbon Steel Forged Flange | High Quality Forged Flanges Manufacturer |

| ASTM A182 Stainless Steel Forged Flange | Duplex Steel Forged Flange |

| Super Duplex Steel Forged Forged Flange | Copper Nickel Forged Pipe Flanges |

| High Nickel Alloy Forged Flanges | Hastelloy Flat Faced Forged Flanges Stockist |

| Titanium ASME B16.47 Series A and B Forged Flanges | Inconel Forged Flanges |

ANSI/ASME B16.5 FORGED FLANGES DIMENSIONS

| Class 150 Forged Flange Dimesions | |||||||||||||||||

|

Nom. Pipe Size |

O | T | TJ | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | D | Thr |

| ½ | 3.5 | 0.38 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 0.88 | 0.62 | 0.9 | 0.84 | 0.56 | 1.81 | 0.62 | 0.12 | 0.38 | 0.62 |

| ¾ | 3.88 | 0.44 | 0.5 | 1.69 | 1.5 | 4-0.62 | 2.75 | 1.09 | 0.82 | 1.11 | 1.05 | 0.56 | 2 | 0.62 | 0.12 | 0.44 | 0.62 |

| 1 | 4.25 | 0.5 | 0.56 | 2 | 1.94 | 4-0.62 | 3.12 | 1.36 | 1.05 | 1.38 | 1.32 | 0.62 | 2.12 | 0.69 | 0.12 | 0.5 | 0.69 |

| 1¼ | 4.62 | 0.56 | 0.62 | 2.5 | 2.31 | 4-0.62 | 3.5 | 1.7 | 1.38 | 1.72 | 1.66 | 0.75 | 2.19 | 0.81 | 0.19 | 0.56 | 0.81 |

| 1½ | 5 | 0.62 | 0.69 | 2.88 | 2.56 | 4-0.62 | 3.88 | 1.95 | 1.61 | 1.97 | 1.9 | 0.81 | 2.38 | 0.88 | 0.25 | 0.62 | 0.88 |

| 2 | 6 | 0.69 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.44 | 2.07 | 2.46 | 2.38 | 0.94 | 2.44 | 1 | 0.31 | 0.69 | 1 |

| 2½ | 7 | 0.81 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.5 | 2.94 | 2.47 | 2.97 | 2.88 | 1.06 | 2.69 | 1.12 | 0.31 | 0.75 | 1.12 |

| 3 | 7.5 | 0.88 | 0.94 | 5 | 4.25 | 4-0.75 | 6 | 3.57 | 3.07 | 3.6 | 3.5 | 1.12 | 2.69 | 1.19 | 0.38 | 0.81 | 1.19 |

| 3½ | 8.5 | 0.88 | 0.94 | 5.5 | 4.81 | 8-0.75 | 7 | 4.07 | 3.55 | 4.1 | 4 | 1.19 | 2.75 | 1.25 | 0.38 | 0.88 | 1.25 |

| 4 | 9 | 0.88 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.5 | 4.57 | 4.03 | 4.6 | 4.5 | 1.25 | 2.94 | 1.31 | 0.44 | 0.94 | 1.31 |

| 5 | 10 | 0.88 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.5 | 5.66 | 5.05 | 5.69 | 5.56 | 1.38 | 3.44 | 1.44 | 0.44 | 0.94 | 1.44 |

| 6 | 11 | 0.94 | 1 | 8.5 | 7.56 | 8-0.88 | 9.5 | 6.72 | 6.07 | 6.75 | 6.63 | 1.5 | 3.44 | 1.56 | 0.5 | 1.06 | 1.56 |

| 8 | 13.5 | 1.06 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 8.72 | 7.98 | 8.75 | 8.63 | 1.69 | 3.94 | 1.75 | 0.5 | 1.25 | 1.75 |

| 10 | 16 | 1.12 | 1.19 | 12.75 | 12 | 12-1.00 | 14.25 | 10.88 | 10.02 | 10.92 | 10.75 | 1.88 | 3.94 | 1.94 | 0.5 | 1.31 | 1.94 |

| 12 | 19 | 1.19 | 1.25 | 15 | 14.38 | 12-1.00 | 17 | 12.88 | 12 | 12.92 | 12.75 | 2.12 | 4.44 | 2.19 | 0.5 | 1.56 | 2.19 |

| 14 | 21 | 1.31 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 14.14 | 13.25 | 14.18 | 14 | 2.19 | 4.94 | 3.12 | 0.5 | 1.63 | 2.25 |

| 16 | 23.5 | 1.38 | 1.44 | 18.5 | 18 | 16-1.12 | 21.25 | 16.16 | 15.25 | 16.19 | 16 | 2.44 | 4.94 | 3.44 | 0.5 | 1.75 | 2.5 |

| 18 | 25 | 1.5 | 1.56 | 21 | 19.88 | 16-1.25 | 22.75 | 18.18 | 17.25 | 18.2 | 18 | 2.62 | 5.44 | 3.81 | 0.5 | 1.94 | 2.69 |

| 20 | 27.5 | 1.62 | 1.69 | 23 | 22 | 20-1.25 | 25 | 20.2 | 19.25 | 20.25 | 20 | 2.81 | 5.62 | 4.06 | 0.5 | 2.13 | 2.88 |

| 22 | 29.5 | 1.75 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 22.22 | 21.25 | 22.25 | 22 | 3.07 | 5.82 | 4.25 | 0.5 | 2.38 | 3.13 |

| 24 | 32 | 1.81 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.5 | 24.25 | 23.25 | 24.25 | 24 | 3.19 | 5.94 | 4.38 | 0.5 | 2.5 | 3.25 |

| Class 300 Forged Flange Dimesions | ||||||||||||||||||

|

Nom. Pipe Size |

O | T | TJ | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

| ½ | 3.75 | 0.5 | 0.56 | 1.38 | 1.5 | 4-0.63 | 2.62 | 0.88 | 0.62 | 0.9 | 0.84 | 0.81 | 2 | 0.88 | 0.12 | 0.93 | 0.38 | 0.62 |

| ¾ | 4.62 | 0.56 | 0.62 | 1.69 | 1.88 | 4-0.75 | 3.25 | 1.09 | 0.82 | 1.11 | 1.05 | 0.94 | 2.19 | 1 | 0.12 | 1.14 | 0.44 | 0.62 |

| 1 | 4.88 | 0.62 | 0.69 | 2 | 2.12 | 4-0.75 | 3.5 | 1.36 | 1.05 | 1.38 | 1.32 | 1 | 2.38 | 1.06 | 0.12 | 1.41 | 0.5 | 0.69 |

| 1¼ | 5.25 | 0.69 | 0.75 | 2.5 | 2.5 | 4-0.75 | 3.88 | 1.7 | 1.38 | 1.72 | 1.66 | 1 | 2.5 | 1.06 | 0.19 | 1.75 | 0.56 | 0.81 |

| 1½ | 6.12 | 0.75 | 0.81 | 2.88 | 2.75 | 4-0.88 | 4.5 | 1.95 | 1.61 | 1.97 | 1.9 | 1.13 | 2.63 | 1.19 | 0.25 | 1.98 | 0.62 | 0.88 |

| 2 | 6.5 | 0.81 | 0.88 | 3.62 | 3.31 | 8-0.75 | 5 | 2.44 | 2.07 | 2.46 | 2.38 | 1.25 | 2.69 | 1.31 | 0.31 | 2.5 | 0.69 | 1.12 |

| 2½ | 7.5 | 0.94 | 1 | 4.12 | 3.94 | 8-0.88 | 5.88 | 2.94 | 2.47 | 2.97 | 2.88 | 1.44 | 2.94 | 1.5 | 0.31 | 3 | 0.75 | 1.25 |

| 3 | 8.25 | 1.06 | 1.12 | 5 | 4.62 | 8-0.88 | 6.62 | 3.57 | 3.07 | 3.6 | 3.5 | 1.63 | 3.06 | 1.69 | 0.38 | 3.63 | 0.81 | 1.25 |

| 3½ | 9 | 1.12 | 1.19 | 5.5 | 5.25 | 8-0.88 | 7.25 | 4.07 | 3.55 | 4.1 | 4 | 1.69 | 3.13 | 1.75 | 0.38 | 4.13 | …. | 1.44 |

| 4 | 10 | 1.19 | 1.25 | 6.19 | 5.75 | 8-0.88 | 7.88 | 4.57 | 4.03 | 4.6 | 4.5 | 1.82 | 3.32 | 1.88 | 0.44 | 4.63 | …. | 1.44 |

| 5 | 11 | 1.31 | 1.38 | 7.31 | 7 | 8-0.88 | 9.25 | 5.66 | 5.05 | 5.69 | 5.56 | 1.94 | 3.82 | 2 | 0.44 | 5.69 | …. | 1.69 |

| 6 | 12.5 | 1.38 | 1.44 | 8.5 | 8.12 | 12-0.88 | 10.62 | 6.72 | 6.07 | 6.75 | 6.63 | 2 | 3.82 | 2.06 | 0.5 | 6.75 | …. | 1.81 |

| 8 | 15 | 1.56 | 1.62 | 10.62 | 10.25 | 12-1.00 | 13 | 8.72 | 7.98 | 8.75 | 8.63 | 2.38 | 4.32 | 2.44 | 0.5 | 8.75 | …. | 2 |

| 10 | 17.5 | 1.81 | 1.88 | 12.75 | 12.62 | 16-1.12 | 15.25 | 10.88 | 10.02 | 10.92 | 10.75 | 2.56 | 4.56 | 3.75 | 0.5 | 10.88 | …. | 2.19 |

| 12 | 20.5 | 1.94 | 2 | 15 | 14.75 | 16-1.25 | 17.75 | 12.88 | 12 | 12.92 | 12.75 | 2.82 | 5.06 | 4 | 0.5 | 12.94 | …. | 2.38 |

| 14 | 23 | 2.06 | 2.12 | 16.25 | 16.75 | 20-1.25 | 20.25 | 14.14 | 13.25 | 14.18 | 14 | 2.94 | 5.56 | 4.38 | 0.5 | 14.19 | …. | 2.5 |

| 16 | 25.5 | 2.19 | 2.25 | 18.5 | 19 | 20-1.38 | 22.5 | 16.16 | 15.25 | 16.19 | 16 | 3.19 | 5.69 | 4.75 | 0.5 | 16.19 | …. | 2.69 |

| 18 | 28 | 2.31 | 2.38 | 21 | 21 | 24-1.38 | 24.75 | 18.18 | 17.25 | 18.2 | 18 | 3.44 | 6.19 | 5.12 | 0.5 | 18.19 | …. | 2.75 |

| 20 | 30.5 | 2.44 | 2.5 | 23 | 23.12 | 24-1.38 | 27 | 20.2 | 19.25 | 20.25 | 20 | 3.69 | 6.32 | 5.5 | 0.5 | 20.19 | …. | 2.88 |

| 22 | 33 | 2.57 | 2.63 | 25.25 | 25.25 | 24-1.63 | 29.25 | 22.22 | 21.25 | 22.25 | 22 | 3.93 | 6.43 | 5.75 | 0.5 | 22.19 | …. | 3.13 |

| 24 | 36 | 2.69 | 2.75 | 27.25 | 27.62 | 24-1.63 | 32 | 24.25 | 23.25 | 24.25 | 24 | 4.13 | 6.56 | 6 | 0.5 | 24.19 | …. | 3.25 |

Dimensions are in inches.

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

| Class 400 Forged Flange Dimesions | |||||||||||||||||

|

Nom. Pipe Size |

O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

| ½ | 3.75 | 0.56 | 1.38 | 1.5 | 4-0.63 | 2.62 | 0.88 | To Be Specified By Purchaser | 0.9 | 0.84 | 0.88 | 2.06 | 0.88 | 0.12 | 0.93 | 0.38 | 0.62 |

| ¾ | 4.62 | 0.62 | 1.69 | 1.88 | 4-0.75 | 3.25 | 1.09 | 1.11 | 1.05 | 1 | 2.25 | 1 | 0.12 | 1.14 | 0.44 | 0.62 | |

| 1 | 4.88 | 0.69 | 2 | 2.12 | 4-.075 | 3.5 | 1.36 | 1.38 | 1.32 | 1.06 | 2.44 | 1.06 | 0.12 | 1.41 | 0.5 | 0.69 | |

| 1¼ | 5.25 | 0.81 | 2.5 | 2.5 | 4-0.75 | 3.88 | 1.7 | 1.72 | 1.66 | 1.12 | 2.62 | 1.12 | 0.19 | 1.75 | 0.56 | 0.81 | |

| 1½ | 6.12 | 0.88 | 2.88 | 2.75 | 4-0.88 | 4.5 | 1.95 | 1.97 | 1.9 | 1.25 | 2.75 | 1.25 | 0.25 | 1.99 | 0.62 | 0.88 | |

| 2 | 6.5 | 1 | 3.62 | 3.31 | 8-0.75 | 5 | 2.44 | 2.46 | 2.38 | 1.44 | 2.88 | 1.44 | 0.31 | 2.5 | 0.69 | 1.12 | |

| 2½ | 7.5 | 1.12 | 4.12 | 3.94 | 8-0.88 | 5.88 | 2.94 | 2.97 | 2.88 | 1.62 | 3.12 | 1.62 | 0.31 | 3 | 0.75 | 1.25 | |

| 3 | 8.25 | 1.25 | 5 | 4.62 | 8-0.88 | 6.62 | 3.57 | 3.6 | 3.5 | 1.81 | 3.25 | 1.81 | 0.38 | 3.63 | 0.81 | 1.38 | |

| 3½ | 9 | 1.38 | 5.5 | 5.25 | 8-1.00 | 7.25 | 4.07 | 4.1 | 4 | 1.94 | 3.38 | 1.94 | 0.38 | 4.13 | …. | 1.56 | |

| 4 | 10 | 1.38 | 6.19 | 5.75 | 8-1.00 | 7.88 | 4.57 | 4.6 | 4.5 | 2 | 3.5 | 2 | 0.44 | 4.63 | …. | 1.44 | |

| 5 | 11 | 1.5 | 7.31 | 7 | 8-1.00 | 9.25 | 5.66 | 5.69 | 5.56 | 2.12 | 4 | 2.12 | 0.44 | 5.69 | …. | 1.69 | |

| 6 | 12.5 | 1.62 | 8.5 | 8.12 | 12-1.00 | 10.62 | 6.72 | 6.75 | 6.63 | 2.25 | 4.06 | 2.25 | 0.5 | 6.75 | …. | 1.81 | |

| 8 | 15 | 1.88 | 10.62 | 10.25 | 12-1.12 | 13 | 8.72 | 8.75 | 8.63 | 2.69 | 4.62 | 2.69 | 0.5 | 8.75 | …. | 2 | |

| 10 | 17.5 | 2.12 | 12.75 | 12.62 | 16-1.25 | 15.25 | 10.88 | 10.92 | 10.75 | 2.88 | 4.88 | 4 | 0.5 | 10.88 | …. | 2.19 | |

| 12 | 20.5 | 2.25 | 15 | 14.75 | 16-1.38 | 17.75 | 12.88 | 12.92 | 12.75 | 3.12 | 5.38 | 4.25 | 0.5 | 12.94 | …. | 2.38 | |

| 14 | 23 | 2.38 | 16.25 | 16.75 | 20-1.38 | 20.25 | 14.14 | 14.18 | 14 | 3.31 | 5.88 | 4.62 | 0.5 | 14.19 | …. | 2.5 | |

| 16 | 25.5 | 2.5 | 18.5 | 19 | 20-1.50 | 22.5 | 16.16 | 16.19 | 16 | 3.69 | 6 | 5 | 0.5 | 16.19 | …. | 2.69 | |

| 18 | 28 | 2.62 | 21 | 21 | 24-1.50 | 24.75 | 18.18 | 18.2 | 18 | 3.88 | 6.5 | 5.38 | 0.5 | 18.19 | …. | 2.75 | |

| 20 | 30.5 | 2.75 | 23 | 23.12 | 24-1.62 | 27 | 20.2 | 20.25 | 20 | 4 | 6.62 | 5.75 | 0.5 | 20.19 | …. | 2.88 | |

| 22 | 33 | 2.88 | 25.25 | 25.25 | 24-1.75 | 29.25 | 22.22 | 22.25 | 22 | 4.25 | 6.75 | 6 | 0.5 | …. | …. | — | |

| 24 | 36 | 3 | 27.25 | 27.62 | 24-1.88 | 32 | 24.25 | 24.25 | 24 | 4.5 | 6.88 | 6.25 | 0.5 | 24.19 | …. | 3.25 | |

Dimensions are in inches.

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

| Class 600 Forged Steel Flange Dimensions | |||||||||||||||||

|

Nom. Pipe Size |

O | T | R | X | #/Dia of Holes | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

| ½ | 3.75 | 0.56 | 1.38 | 1.5 | 4-0.63 | 2.62 | 0.88 | To Be Specified By Purchaser | 0.9 | 0.84 | 0.88 | 2.06 | 0.88 | 0.12 | 0.93 | 0.38 | 0.62 |

| ¾ | 4.62 | 0.62 | 1.69 | 1.88 | 4-0.75 | 3.25 | 1.09 | 1.11 | 1.05 | 1 | 2.25 | 1 | 0.12 | 1.14 | 0.44 | 0.62 | |

| 1 | 4.88 | 0.69 | 2 | 2.12 | 4-0.75 | 3.5 | 1.36 | 1.38 | 1.32 | 1.06 | 2.44 | 1.06 | 0.12 | 1.41 | 0.5 | 0.69 | |

| 1¼ | 5.25 | 0.81 | 2.5 | 2.5 | 4-0.75 | 3.88 | 1.7 | 1.72 | 1.66 | 1.12 | 2.62 | 1.12 | 0.19 | 1.75 | 0.56 | 0.81 | |

| 1½ | 6.12 | 0.88 | 2.88 | 2.75 | 4-0.88 | 4.5 | 1.95 | 1.97 | 1.9 | 1.25 | 2.75 | 1.25 | 0.25 | 1.99 | 0.62 | 0.88 | |

| 2 | 6.5 | 1 | 3.62 | 3.31 | 8-0.75 | 5 | 2.44 | 2.46 | 2.38 | 1.44 | 2.88 | 1.44 | 0.31 | 2.5 | 0.69 | 1.12 | |

| 2½ | 7.5 | 1.12 | 4.12 | 3.94 | 8-0.88 | 5.88 | 2.94 | 2.97 | 2.88 | 1.62 | 3.12 | 1.62 | 0.31 | 3 | 0.75 | 1.25 | |

| 3 | 8.25 | 1.25 | 5 | 4.62 | 8-0.88 | 6.62 | 3.57 | 3.6 | 3.5 | 1.81 | 3.25 | 1.81 | 0.38 | 3.63 | 0.81 | 1.38 | |

| 3½ | 9 | 1.38 | 5.5 | 5.25 | 8-1.00 | 7.25 | 4.07 | 4.1 | 4 | 1.94 | 3.38 | 1.94 | 0.38 | 4.13 | …. | 1.56 | |

| 4 | 10.75 | 1.5 | 6.19 | 6 | 8-1.00 | 8.5 | 4.57 | 4.6 | 4.5 | 2.12 | 4 | 2.12 | 0.44 | 4.63 | …. | 1.62 | |

| 5 | 13 | 1.75 | 7.31 | 7.44 | 8-1.12 | 10.5 | 5.66 | 5.69 | 5.56 | 2.38 | 4.5 | 2.38 | 0.44 | 5.69 | …. | 1.88 | |

| 6 | 14 | 1.88 | 8.5 | 8.75 | 12-1.12 | 11.5 | 6.72 | 6.75 | 6.63 | 2.62 | 4.62 | 2.62 | 0.5 | 6.75 | …. | 2 | |

| 8 | 16.5 | 2.19 | 10.62 | 10.75 | 12-1.25 | 13.75 | 8.72 | 8.75 | 8.63 | 3 | 5.25 | 3 | 0.5 | 8.75 | …. | 2.25 | |

| 10 | 20 | 2.5 | 12.75 | 13.5 | 16-1.38 | 17 | 10.88 | 10.92 | 10.75 | 3.38 | 6 | 4.38 | 0.5 | 10.88 | …. | 2.56 | |

| 12 | 22 | 2.62 | 15 | 15.75 | 20-1.38 | 19.25 | 12.88 | 12.92 | 12.75 | 3.62 | 6.12 | 4.62 | 0.5 | 12.94 | …. | 2.75 | |

| 14 | 23.75 | 2.75 | 16.25 | 17 | 20-1.50 | 20.75 | 14.14 | 14.18 | 14 | 3.69 | 6.5 | 5 | 0.5 | 14.19 | …. | 2.88 | |

| 16 | 27 | 3 | 18.5 | 19.5 | 20-1.63 | 23.75 | 16.16 | 16.19 | 16 | 4.19 | 7 | 5.5 | 0.5 | 16.19 | …. | 3.06 | |

| 18 | 29.25 | 3.25 | 21 | 21.5 | 20-1.75 | 25.75 | 18.18 | 18.2 | 18 | 4.62 | 7.25 | 6 | 0.5 | 18.19 | …. | 3.12 | |

| 20 | 32 | 3.5 | 23 | 24 | 24-1.75 | 28.5 | 20.2 | 20.25 | 20 | 5 | 7.5 | 6.5 | 0.5 | 20.19 | …. | 3.25 | |

| 22 | 34.25 | 3.75 | 25.25 | 26.25 | 24-1.75 | 30.63 | 22.22 | 22.25 | 22 | 5.25 | 7.75 | 6.88 | 0.5 | …. | …. | — | |

| 24 | 37 | 4 | 27.25 | 28.25 | 24-2.00 | 33 | 24.25 | 24.25 | 24 | 5.5 | 8 | 7.25 | 0.5 | 24.19 | …. | 3.62 | |

Dimensions are in inches.

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

| Nom. Pipe Size | O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | Thr |

| Sizes 1/2″ through 2 1/2″ are identical to class 1500. | ||||||||||||||||

| 3 | 9.5 | 1.5 | 5 | 5 | 8-1.00 | 7.5 | 3.57 | To Be Specified By Purchaser | 3.6 | 3.5 | 2.12 | 4 | 2.12 | 0.38 | 3.63 | 1.62 |

| 4 | 11.5 | 1.75 | 6.19 | 6.25 | 8-1.25 | 9.25 | 4.57 | 4.6 | 4.5 | 2.75 | 4.5 | 2.75 | 0.44 | 4.63 | 1.88 | |

| 5 | 13.75 | 2 | 7.31 | 7.5 | 8-1.38 | 11 | 5.66 | 5.69 | 5.56 | 3.12 | 5 | 3.12 | 0.44 | 5.69 | 2.12 | |

| 6 | 15 | 2.19 | 8.5 | 9.25 | 12-1.25 | 12.5 | 6.72 | 6.75 | 6.63 | 3.38 | 5.5 | 3.38 | 0.5 | 6.75 | 2.25 | |

| 8 | 18.5 | 2.5 | 10.63 | 11.75 | 12-1.50 | 15.5 | 8.72 | 8.75 | 8.63 | 4 | 6.38 | 4.5 | 0.5 | 8.75 | 2.5 | |

| 10 | 21.5 | 2.75 | 12.75 | 14.5 | 16-1.50 | 18.5 | 10.88 | 10.92 | 10.75 | 4.25 | 7.25 | 5 | 0.5 | 10.88 | 2.81 | |

| 12 | 24 | 3.12 | 15 | 16.5 | 20-1.50 | 21 | 12.88 | 12.92 | 12.75 | 4.63 | 7.88 | 5.62 | 0.5 | 12.94 | 3 | |

| 14 | 25.25 | 3.38 | 16.25 | 17.75 | 20-1.63 | 22 | 14.14 | 14.18 | 14 | 5.12 | 8.38 | 6.12 | 0.5 | 14.19 | 3.25 | |

| 16 | 27.75 | 3.5 | 18.5 | 20 | 20-1.75 | 24.25 | 16.16 | 16.19 | 16 | 5.25 | 8.5 | 6.5 | 0.5 | 16.19 | 3.38 | |

| 18 | 31 | 4 | 21 | 22.25 | 20-2.00 | 27 | 18.18 | 18.2 | 18 | 6 | 9 | 7.5 | 0.5 | 18.19 | 3.5 | |

| 20 | 33.75 | 4.25 | 23 | 24.5 | 20-2.13 | 29.5 | 20.2 | 20.25 | 20 | 6.25 | 9.75 | 8.25 | 0.5 | 20.19 | 3.62 | |

| 24 | 41 | 5.5 | 27.25 | 29.5 | 20-2.63 | 35.5 | 24.25 | 24.25 | 24 | 8 | 11.5 | 10.5 | 0.5 | 24.19 | 4 | |

Dimensions are in inches.

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

| Class 1500 Forged Flange Dimensions | |||||||||||||||||

|

Nom. Pipe Size |

O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

| ½ | 4.75 | 0.88 | 1.38 | 1.5 | 4-0.88 | 3.25 | 0.88 | To Be Specified By Purchaser | 0.9 | 0.84 | 1.25 | 2.38 | 1.25 | 0.12 | 0.93 | 0.38 | 0.88 |

| ¾ | 5.12 | 1 | 1.69 | 1.75 | 4-0.88 | 3.5 | 1.09 | 1.11 | 1.05 | 1.38 | 2.75 | 1.38 | 0.12 | 1.14 | 0.44 | 1 | |

| 1 | 5.88 | 1.12 | 2 | 2.06 | 4-1.00 | 4 | 1.36 | 1.38 | 1.32 | 1.62 | 2.88 | 1.62 | 0.12 | 1.41 | 0.5 | 1.12 | |

| 1¼ | 6.25 | 1.12 | 2.5 | 2.5 | 4-1.00 | 4.38 | 1.7 | 1.72 | 1.66 | 1.62 | 2.88 | 1.62 | 0.19 | 1.75 | 0.56 | 1.19 | |

| 1½ | 7 | 1.25 | 2.88 | 2.75 | 4-1.12 | 4.88 | 1.95 | 1.97 | 1.9 | 1.75 | 3.25 | 1.75 | 0.25 | 1.99 | 0.62 | 1.25 | |

| 2 | 8.5 | 1.5 | 3.63 | 4.12 | 8-1.00 | 6.5 | 2.44 | 2.46 | 2.38 | 2.25 | 4 | 2.25 | 0.31 | 2.5 | 0.69 | 1.5 | |

| 2½ | 9.62 | 1.62 | 4.13 | 4.88 | 8-1.12 | 7.5 | 2.94 | 2.97 | 2.88 | 2.5 | 4.12 | 2.5 | 0.31 | 3 | 0.75 | 1.88 | |

| 3 | 10.5 | 1.88 | 5 | 5.25 | 8-1.25 | 8 | …. | 3.6 | 3.5 | …. | 4.62 | 2.88 | 0.38 | …. | …. | …. | |

| 4 | 12.25 | 2.12 | 6.19 | 6.38 | 8-1.38 | 9.5 | …. | 4.6 | 4.5 | …. | 4.88 | 3.56 | 0.44 | …. | …. | …. | |

| 5 | 14.75 | 2.88 | 7.31 | 7.75 | 8-1.63 | 11.5 | …. | 5.69 | 5.56 | …. | 6.12 | 4.12 | 0.44 | …. | …. | …. | |

| 6 | 15.5 | 3.25 | 8.5 | 9 | 12-1.50 | 12.5 | …. | 6.75 | 6.63 | …. | 6.75 | 4.69 | 0.5 | …. | …. | …. | |

| 8 | 19 | 3.62 | 10.63 | 11.5 | 12-1.75 | 15.5 | …. | 8.75 | 8.63 | …. | 8.38 | 5.62 | 0.5 | …. | …. | …. | |

| 10 | 23 | 4.25 | 12.75 | 14.5 | 12-2.00 | 19 | …. | 10.92 | 10.75 | …. | 10 | 7 | 0.5 | …. | …. | …. | |

| 12 | 26.5 | 4.88 | 15 | 17.75 | 16-2.12 | 22.5 | …. | 12.92 | 12.75 | …. | 11.12 | 8.62 | 0.5 | …. | …. | …. | |

| 14 | 29.5 | 5.25 | 16.25 | 19.5 | 16-2.38 | 25 | …. | 14.18 | 14 | …. | 11.75 | 9.5 | 0.5 | …. | …. | …. | |

| 16 | 32.5 | 5.75 | 18.5 | 21.75 | 16-2.63 | 27.75 | …. | 16.19 | 16 | …. | 12.25 | 10.25 | 0.5 | …. | …. | …. | |

| 18 | 36 | 6.38 | 21 | 23.5 | 16-2.88 | 30.5 | …. | 18.2 | 18 | …. | 12.88 | 10.88 | 0.5 | …. | …. | …. | |

| 20 | 38.75 | 7 | 23 | 25.25 | 16-3.12 | 32.75 | …. | 20.25 | 20 | …. | 14 | 11.5 | 0.5 | …. | …. | …. | |

| 24 | 46 | 8 | 27.25 | 30 | 16-3.63 | 39 | …. | 24.25 | 24 | …. | 16 | 13 | 0.5 | …. | …. | …. | |

Dimensions are in inches.

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

| Nom. Pipe Size | O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B2b | B3 | H | L | L2 | L3 | r | C | Thr |

| ½ | 5.25 | 1.19 | 1.38 | 1.69 | 4-0.88 | 3.5 | To Be Specified By Purchaser | 0.9 | 0.84 | 1.56 | 2.88 | 1.56 | 0.12 | 0.93 | 1.12 |

| ¾ | 5.5 | 1.25 | 1.69 | 2 | 4-0.88 | 3.75 | 1.11 | 1.05 | 1.69 | 3.12 | 1.69 | 0.12 | 1.14 | 1.25 | |

| 1 | 6.25 | 1.38 | 2 | 2.25 | 4-1.00 | 4.25 | 1.38 | 1.32 | 1.88 | 3.5 | 1.88 | 0.12 | 1.41 | 1.38 | |

| 1¼ | 7.25 | 1.5 | 2.5 | 2.88 | 4-1.12 | 5.13 | 1.72 | 1.66 | 2.06 | 3.75 | 2.06 | 0.19 | 1.75 | 1.5 | |

| 1½ | 8 | 1.75 | 2.88 | 3.12 | 4-1.25 | 5.75 | 1.97 | 1.9 | 2.38 | 4.38 | 2.38 | 0.25 | 1.99 | 1.75 | |

| 2 | 9.25 | 2 | 3.63 | 3.75 | 8-1.12 | 6.75 | 2.46 | 2.38 | 2.75 | 5 | 2.75 | 0.31 | 2.5 | 2 | |

| 2½ | 10.5 | 2.25 | 4.13 | 4.5 | 8-1.25 | 7.75 | 2.97 | 2.88 | 3.12 | 5.62 | 3.12 | 0.31 | 3 | 2.25 | |

| 3 | 12 | 2.62 | 5 | 5.25 | 8-1.38 | 9 | 3.6 | 3.5 | …. | 6.62 | 3.62 | 0.38 | …. | …. | |

| 4 | 14 | 3 | 6.19 | 6.5 | 8-1.63 | 10.75 | 4.6 | 4.5 | …. | 7.5 | 4.25 | 0.44 | …. | …. | |

| 5 | 16.5 | 3.62 | 7.31 | 8 | 8-1.88 | 12.75 | 5.69 | 5.56 | …. | 9 | 5.12 | 0.44 | …. | …. | |

| 6 | 19 | 4.25 | 8.5 | 9.25 | 8-2.12 | 14.5 | 6.75 | 6.63 | …. | 10.75 | 6 | 0.5 | …. | …. | |

| 8 | 21.75 | 5 | 10.63 | 12 | 12-2.12 | 17.25 | 8.75 | 8.63 | …. | 12.5 | 7 | 0.5 | …. | …. | |

| 10 | 26.5 | 6.5 | 12.75 | 14.75 | 12-2.63 | 21.25 | 10.92 | 10.75 | …. | 16.5 | 9 | 0.5 | …. | …. | |

| 12 | 30 | 7.25 | 15 | 17.38 | 12-2.88 | 24.38 | 12.92 | 12.75 | …. | 18.25 | 10 | 0.5 | …. | …. |

Dimensions are in inches.

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

ASME B16.5 Forged Flanges are known to deliver exceptional performance and are generally developed for

meeting the demands. We oer a broad range of Forged Flanges through a worldwide network of stock-keeping

branches. These Forged Flange is use in various industries like :

Stainless Steel Forged Flanges uses in Oil and Gas Pipeline

Forged Flanges uses in Chemical Industry

Alloy Steel Forged Flanges uses in Plumbing

Flat Faced Forged Flanges uses in Heating

Forged Pipe Flanges uses in Water Supply Systems

ANSI B16.5 Forged Forged Flanges uses in Power Plant

Forged Plate Flanges uses in Paper & Pulp Industry

Forged Flange uses in General Purpose Applications

Steel Forged Flanges uses in Fabrication Industry

Forged Flange uses in Food Processing Industry

Forged Flanges uses in Structural Pipe

| MIDDLE EAST | AFRICA | NORTH AMERICA | EUROPE | ASIA | SOUTH AMERICA |

| Saudi Arabia | Nigeria | Usa | Russia | India | Argentina |

| Iran | Algeria | Canada | Norway | Singapore | Bolivia |

| Iraq | Angola | Mexico | Germany | Malaysia | Brazil |

| Uae | South Africa | Panama | France | Indonesia | Chile |

| Qatar | Libya | Costa Rica | Italy | Thailand | Venezuela |

| Bahrain | Egypt | Puerto Rica | Uk | Vietnam | Colombia |

| Oman | Sudan | Trinidad And Tobago | Spain | South Korea | Ecuador |

| Kuwait | Equatorial Guinea | Jamaica | Ukraine | Japan | Guyana |

| Turkey | The Republic Of Congo | Bahamas | Netherland | Sri Lanka | Paraguay |

| Yemen | Gabon | Denmark | Belgium | Maldives | Uruguay |

| Syria | Greece | Bangladesh | |||

| Jordan | Czech Republic | Mayanmar | |||

| Cyprus | Portugal | Taiwan | |||

| Hungary | Cambodia | ||||

| Albania | |||||

| Austria | |||||

| Switzerland | |||||

| Slovakia | |||||

| Finland | |||||

| Ireland | |||||

| Croatia | |||||

| Slovenia | |||||

| Malta |

Phone+86 151 277 20688

Phone+86 151 277 20688 Tel+86 151 277 20688

Tel+86 151 277 20688 E-mailsales@hgffgroup.com

E-mailsales@hgffgroup.com