+86 151 277 20688

+86 151 277 20688

sales@hgffgroup.com

sales@hgffgroup.com

HGFF Group Co.,Ltd is a Supplier of custom spiral wound gaskets. HGFF engineered spiral wound gaskets are ideal for applications that demand a gasket with the highest-quality flexibility and recovery to maintain a seal even in conditions characterized by fluctuating temperature and pressure.

HGFF Group Co.,Ltd is a Supplier of custom spiral wound gaskets. HGFF engineered spiral wound gaskets are ideal for applications that demand a gasket with the highest-quality flexibility and recovery to maintain a seal even in conditions characterized by fluctuating temperature and pressure.

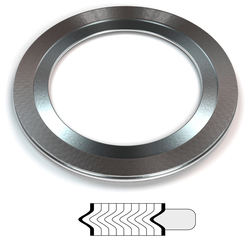

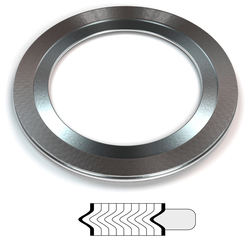

Composed of a steel centering (outer) ring, a spiral wound sealing strip (filler) and an inner ring made of special steel, spiral wound gaskets are created by winding alternating strips of metal and filler material. Depending on the chemical compatibility requirements, the filler and winding material can be changed.

The spiral wound gasket depends upon the mechanical characteristics of a formed metal spiral strip, rather than the compressive virtues of more traditional gasket materials. This makes it particularly suitable for low or fluctuating bolt loads. The sealing strips, or fillers, are usually graphite, although other materials such as PTFE, Non-Asbestos, ceramic., may be used, the windings are always s/steel

These gaskets are manufactured to International specifications such as ASME, DIN, JIS, BS We also manufacture to customer’s specifications

| max Pressure [psi] | ASME B16.5 2500 Class |

| Minimum initial stress [DIN E 2505 part 2] [N/mm2] | 50 |

| Maximum initial stress [DIN E 2505 part 2] [N/mm2] | 300 |

| M-Value | 3 |

| Y- Value [psi] | 10000 |

| Gasket required flange roughness [Ra micron] | 3,2-6,3 |

| Gasket required flange roughness [RMS] | 125-250 |

| Advice Seating stress at assembly [psi] | 12500 |

| ROTT [Gb] | 0.341 |

| ROTT [a] | 0.341 |

| ROTT [Gs”] | 0.341 |

Phone+86 151 277 20688

Phone+86 151 277 20688 Tel+86 151 277 20688

Tel+86 151 277 20688 E-mailsales@hgffgroup.com

E-mailsales@hgffgroup.com