+86 151 277 20688

+86 151 277 20688

sales@hgffgroup.com

sales@hgffgroup.com

We, HGFF Group Co., Ltd. is on a mission to fudge together resources and processes to invent new products that are quality driven and user-friendly. We home in on improving customer experience through

improving our delivery standards. We are a manufacturer, supplier and exporter of ASME B16.5 Flanges that are also identified and referred as ANSI B16.5 Flanges by industries, manufacturers and engineers. Our Stainless Steel ASME B16.5 Flanges tend to remain tough at moderately high-temperature services, while our Carbon Steel ANSI B16.5 Flanges have a higher resistance to local corrosion. The food processing and plastic industry is a major user of ASME B16.5 Alloy 20 Flanges that are not only economical but also withstand carbide

precipitation. We supply ASME/ANSI B16.5 Flanges in Classes 150#, 300#, 600#,900#, 1500#, 2500#, etc.

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629,

DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Material & Grades of ASME B16.5 Flanges :

Stainless Steel ASME B16.5 Flanges :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel ASME B16.5 Flanges :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel ASME B16.5 Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel ASME B16.5 Flanges : ASTM A350, LF2, LF3

Alloy Steel ASME B16.5 Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel ASME B16.5 Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C

71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy ASME B16.5 Flanges :

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS

No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel

600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No.

N10276), Alloy 20 (UNS No. N08020)

| ASME B16.5 Flange | ASME B16.5 Class 150 Forged Flanges |

| ASME B16.5 Class 150 Flange | ASME B16.5 Flange Dimensions |

| ASME B16.5 Class 300 Flanges | Flanges as per ASME B16.5 |

| Stainless Steel ASME B16.5 Flanges | Flange ASME B16.5 Class 150 |

| Carbon Steel ASME B16.5 Flanges | ASME B16.5 Loose Flanges |

| ASME B16.5 Class 600 Flange | ASME B16.5 Flange RF |

| ANSI B16.5 Class 2500 Flange | ASME B16.5 Class 900 Flanges |

| Carbon Steel ASME B16.5 Flange | High Quality ASME B16.5 Flanges |

| Flange ANSI ASME B16.5 | Flange ASME B16.5 Class 400 |

| ASME B16.5 Class 600 Blind Flange | Duplex Steel ASME B16.5 Flange |

| Super Duplex Steel ASME B16.5 Flange | Copper Nickel ASME B16.5 Pipe Flanges |

| High Nickel Alloy ASME B16.5 Flanges | Hastelloy ASME B16.5 Flanges |

| ANSI B16.5 Class 2500 Flanges | Inconel ASME B16.5 Flanges |

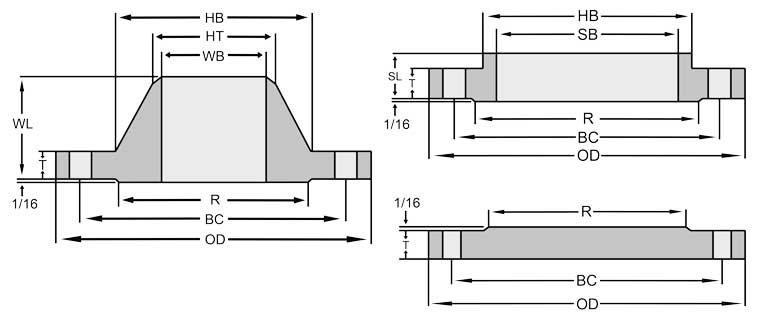

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

DIMENSIONS ARE IN INCHES

Bolt hole diameter 1/8″ larger than bolt diameter

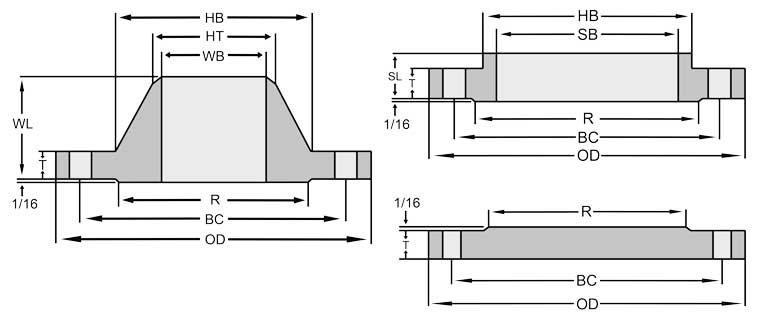

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. Hub Top | SO LTH | WN LTH |

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.75 | 0.5 | 1.38 | 4 | 0.63 | 2.62 | 0.88 | 0.62 | 1.5 | 0.84 | 0.81 | 2 |

| 3⁄4 | 4.62 | 0.56 | 1.69 | 4 | 0.75 | 3.25 | 1.09 | 0.82 | 1.88 | 1.05 | 0.94 | 2.19 |

| 1 | 4.88 | 0.62 | 2 | 4 | 0.75 | 3.5 | 1.36 | 1.05 | 2.12 | 1.32 | 1 | 2.38 |

| 11⁄4 | 5.25 | 0.69 | 2.5 | 4 | 0.75 | 3.88 | 1.7 | 1.38 | 2.5 | 1.66 | 1 | 2.5 |

| 11⁄2 | 6.12 | 0.75 | 2.88 | 4 | 0.88 | 4.5 | 1.95 | 1.61 | 2.75 | 1.9 | 1.13 | 2.63 |

| 2 | 6.5 | 0.81 | 3.62 | 8 | 0.75 | 5 | 2.44 | 2.07 | 3.31 | 2.38 | 1.25 | 2.69 |

| 21⁄2 | 7.5 | 0.94 | 4.12 | 8 | 0.88 | 5.88 | 2.94 | 2.47 | 3.94 | 2.88 | 1.44 | 2.94 |

| 3 | 8.25 | 1.06 | 5 | 8 | 0.88 | 6.62 | 3.57 | 3.07 | 4.62 | 3.5 | 1.63 | 3.06 |

| 31⁄2 | 9 | 1.12 | 5.5 | 8 | 0.88 | 7.25 | 4.07 | 3.55 | 5.25 | 4 | 1.69 | 3.13 |

| 4 | 10 | 1.19 | 6.19 | 8 | 0.88 | 7.88 | 4.57 | 4.03 | 5.75 | 4.5 | 1.82 | 3.32 |

| 5 | 11 | 1.31 | 7.31 | 8 | 0.88 | 9.25 | 5.66 | 5.05 | 7 | 5.56 | 1.94 | 3.82 |

| 6 | 12.5 | 1.38 | 8.5 | 12 | 0.88 | 10.62 | 6.72 | 6.07 | 8.12 | 6.63 | 2 | 3.82 |

| 8 | 15 | 1.56 | 10.62 | 12 | 1 | 13 | 8.72 | 7.98 | 10.25 | 8.63 | 2.38 | 4.32 |

| 10 | 17.5 | 1.81 | 12.75 | 16 | 1.12 | 15.25 | 10.88 | 10.02 | 12.62 | 10.75 | 2.56 | 4.56 |

| 12 | 20.5 | 1.94 | 15 | 16 | 1.25 | 17.75 | 12.88 | 12 | 14.75 | 12.75 | 2.82 | 5.06 |

| 14 | 23 | 2.06 | 16.25 | 20 | 1.25 | 20.25 | 14.14 | 13.25 | 16.75 | 14 | 2.94 | 5.56 |

| 16 | 25.5 | 2.19 | 18.5 | 20 | 1.38 | 22.5 | 16.16 | 15.25 | 19 | 16 | 3.19 | 5.69 |

| 18 | 28 | 2.31 | 21 | 24 | 1.38 | 24.75 | 18.18 | 17.25 | 21 | 18 | 3.44 | 6.19 |

| 20 | 30.5 | 2.44 | 23.12 | 24 | 1.38 | 27 | 20.2 | 19.25 | 23.12 | 20 | 3.69 | 6.32 |

| 22 | 33 | 2.57 | 25.25 | 24 | 1.63 | 29.25 | 22.22 | 21.25 | 25.25 | 22 | 3.93 | 6.43 |

| 24 | 36 | 2.69 | 27.62 | 24 | 1.63 | 32 | 24.25 | 23.25 | 27.62 | 24 | 4.13 | 6.56 |

For flanges type 21 the outside hub diameter approximately corresponds to the outside pipe diameter.

Note : The p/t rating from ASME B16.5 apply only for flange type 05, 11, 12, 13 and 21 having nominal sizes up to and including DN 600. The p/t rating of all other flanges shall be agreed between the manufacturer and the purchaser.

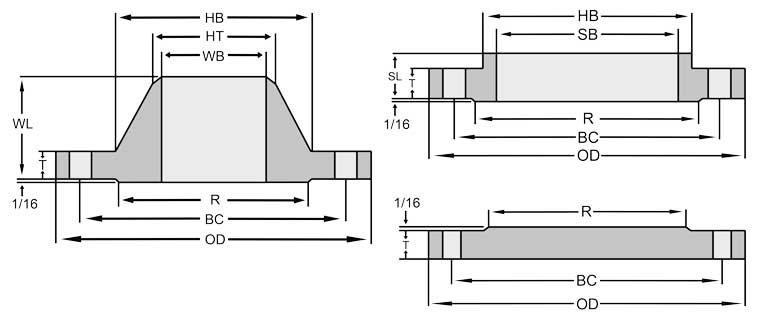

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | Dia. Hub Base | Dia. Hub Top | SO LTH | WN LTH | * WN Bore ID |

| (OD) | (T) | (R) | (BC) | (SB) | (HB) | (HT) | (SL) | (WL) | (WB) | |||

| 1⁄2 | 3.75 | 0.56 | 1.38 | 4 | 0.63 | 2.62 | 0.88 | 1.5 | 0.84 | 0.88 | 2.06 | * |

| 3⁄4 | 4.62 | 0.62 | 1.69 | 4 | 0.75 | 3.25 | 1.09 | 1.88 | 1.05 | 1 | 2.25 | * |

| 1 | 4.88 | 0.69 | 2 | 4 | 0.75 | 3.5 | 1.36 | 2.12 | 1.32 | 1.06 | 2.44 | * |

| 11⁄4 | 5.25 | 0.81 | 2.5 | 4 | 0.75 | 3.88 | 1.7 | 2.5 | 1.66 | 1.12 | 2.62 | * |

| 11⁄2 | 6.12 | 0.88 | 2.88 | 4 | 0.88 | 4.5 | 1.95 | 2.75 | 1.9 | 1.25 | 2.75 | * |

| 2 | 6.5 | 1 | 3.62 | 8 | 0.75 | 5 | 2.44 | 3.31 | 2.38 | 1.44 | 2.88 | * |

| 21⁄2 | 7.5 | 1.12 | 4.12 | 8 | 0.88 | 5.88 | 2.94 | 3.94 | 2.88 | 1.62 | 3.12 | * |

| 3 | 8.25 | 1.25 | 5 | 8 | 0.88 | 6.62 | 3.57 | 4.62 | 3.5 | 1.81 | 3.25 | * |

| 31⁄2 | 9 | 1.38 | 5.5 | 8 | 1 | 7.25 | 4.07 | 5.25 | 4 | 1.94 | 3.38 | * |

| 4 | 10 | 1.38 | 6.19 | 8 | 1 | 7.88 | 4.57 | 5.75 | 4.5 | 2 | 3.5 | * |

| 5 | 11 | 1.5 | 7.31 | 8 | 1 | 9.25 | 5.66 | 7 | 5.56 | 2.12 | 4 | * |

| 6 | 12.5 | 1.62 | 8.5 | 12 | 1 | 10.62 | 6.72 | 8.12 | 6.63 | 2.25 | 4.06 | * |

| 8 | 15 | 1.88 | 10.62 | 12 | 1.12 | 13 | 8.72 | 10.25 | 8.63 | 2.69 | 4.62 | * |

| 10 | 17.5 | 2.12 | 12.75 | 16 | 1.25 | 15.25 | 10.88 | 12.62 | 10.75 | 2.88 | 4.88 | * |

| 12 | 20.5 | 2.25 | 15 | 16 | 1.38 | 17.75 | 12.88 | 14.75 | 12.75 | 3.12 | 5.38 | * |

| 14 | 23 | 2.38 | 16.25 | 20 | 1.38 | 20.25 | 14.14 | 16.75 | 14 | 3.31 | 5.88 | * |

| 16 | 25.5 | 2.5 | 18.5 | 20 | 1.5 | 22.5 | 16.16 | 19 | 16 | 3.69 | 6 | * |

| 18 | 28 | 2.62 | 21 | 24 | 1.5 | 24.75 | 18.18 | 21 | 18 | 3.88 | 6.5 | * |

| 20 | 30.5 | 2.75 | 23.12 | 24 | 1.62 | 27 | 20.2 | 23.12 | 20 | 4 | 6.62 | * |

| 22 | 33 | 2.88 | 25.25 | 24 | 1.75 | 29.25 | 22.22 | 25.25 | 22 | 4.25 | 6.75 | * |

| 24 | 36 | 3 | 27.25 | 24 | 1.88 | 32 | 24.25 | 27.62 | 24 | 4.5 | 6.88 | * |

ASME B16.5 ASME B16.5 Flanges are known to deliver exceptional performance and are generally developed for

meeting the demands. We oer a broad range of ASME B16.5 Flanges through a worldwide network of stockkeeping branches. These ASME B16.5 Flange is use in various industries like :

Stainless Steel ASME B16.5 Flanges uses in Oil and Gas Pipeline

ASME B16.5 Flanges uses in Chemical Industry

Alloy Steel ASME B16.5 Flanges uses in Plumbing

ASME B16.5 Flanges uses in Heating

ASME B16.5 Pipe Flanges uses in Water Supply Systems

ANSI B16.5 ASME B16.5 ASME B16.5 Flanges uses in Power Plant

ASME B16.5 Flanges uses in Paper & Pulp Industry

ASME B16.5 Flange uses in General Purpose Applications

Steel ASME B16.5 Flanges uses in Fabrication Industry

ASME B16.5 Flange uses in Food Processing Industry

ASME B16.5 Flanges uses in Structural Pipe

| MIDDLE EAST | AFRICA | NORTH AMERICA | EUROPE | ASIA | SOUTH AMERICA |

| Saudi Arabia | Nigeria | Usa | Russia | India | Argentina |

| Iran | Algeria | Canada | Norway | Singapore | Bolivia |

| Iraq | Angola | Mexico | Germany | Malaysia | Brazil |

| Uae | South Africa | Panama | France | Indonesia | Chile |

| Qatar | Libya | Costa Rica | Italy | Thailand | Venezuela |

| Bahrain | Egypt | Puerto Rica | Uk | Vietnam | Colombia |

| Oman | Sudan | Trinidad And Tobago | Spain | South Korea | Ecuador |

| Kuwait | Equatorial Guinea | Jamaica | Ukraine | Japan | Guyana |

| Turkey | The Republic Of Congo | Bahamas | Netherland | Sri Lanka | Paraguay |

| Yemen | Gabon | Denmark | Belgium | Maldives | Uruguay |

| Syria | Greece | Bangladesh | |||

| Jordan | Czech Republic | Mayanmar | |||

| Cyprus | Portugal | Taiwan | |||

| Hungary | Cambodia | ||||

| Albania | |||||

| Austria | |||||

| Switzerland | |||||

| Slovakia | |||||

| Finland | |||||

| Ireland | |||||

| Croatia | |||||

| Slovenia | |||||

| Malta |

Phone+86 151 277 20688

Phone+86 151 277 20688 Tel+86 151 277 20688

Tel+86 151 277 20688 E-mailsales@hgffgroup.com

E-mailsales@hgffgroup.com