+86 151 277 20688

+86 151 277 20688

sales@hgffgroup.com

sales@hgffgroup.com

We, HGFF Group Co., Ltd. extends a product line that is impeccable and unique with a complete customer satisfaction experience. We are manufacturers, suppliers, and exporters of a range of Ring Type Joint Flanges

We, HGFF Group Co., Ltd. extends a product line that is impeccable and unique with a complete customer satisfaction experience. We are manufacturers, suppliers, and exporters of a range of Ring Type Joint Flanges

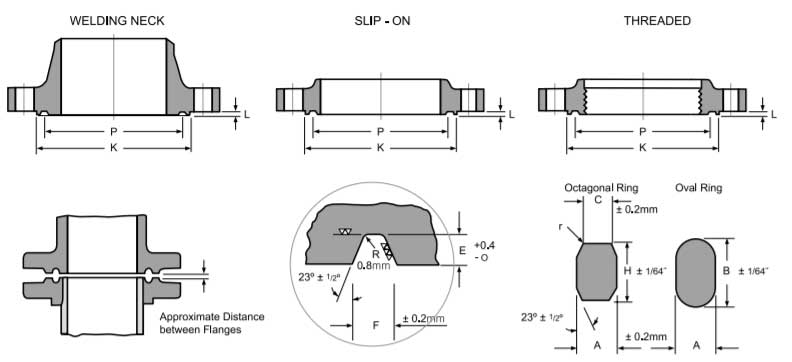

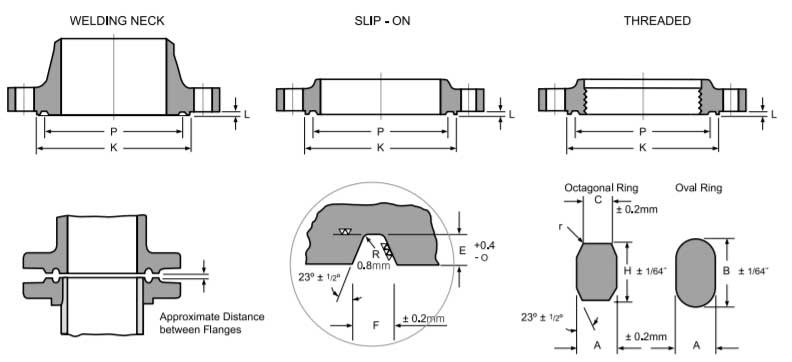

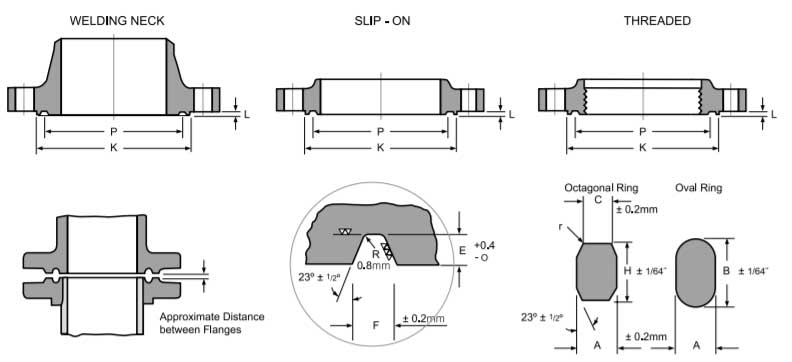

(RTJ) that are best-in-class. A Ring type joint flange(RTJ) is a machined metallic ring with a deep groove cut into its face. This groove rests a metal ring which gets compressed when the connecting bolts of the flange are tightened. This compression results in a leak-proof, close-fitting seal on the pipe or connection. Stainless Steel Ring type Joint Flanges are classically used in high-pressure and high-temperature services, while Carbon Steel Ring type Joint Flanges are spill-proof.

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629,

DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

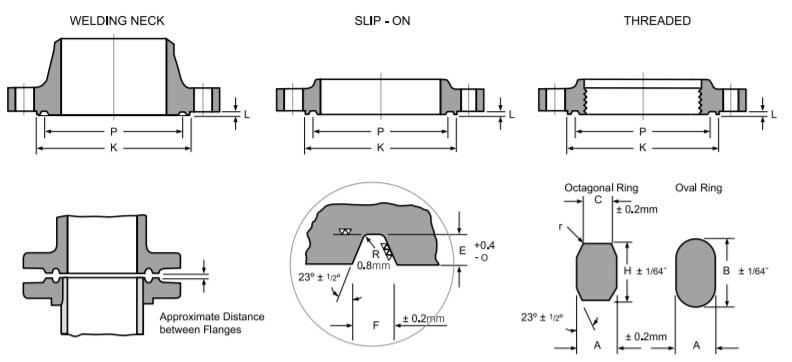

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Material & Grades of Ring Type Joint Flanges (RTJ) :

Stainless Steel Ring Type Joint Flanges :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Ring Type Joint Flanges :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel Ring Type Joint Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel Ring Type Joint Flanges : ASTM A350, LF2, LF3

Alloy Steel Ring Type Joint Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel Ring Type Joint Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10),

C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy Ring Type Joint Flanges :

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS

No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel

600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No.

N10276), Alloy 20 (UNS No. N08020)

| ANSI B16.5 Ring Type Joint Flanges | Raised Face Ring Type joint Flange |

| RTJ Ring Type joint Flange | ASME B16.5 RTJ Flange Dimensions |

| ASME B16.5 Ring Type Joint Flanges | ANSI B16.5 Class 150 Ring Type joint Flanges |

| Class 150 Ring Type Joint Flanges | Flat Face Ring Type joint flange |

| Ring Type Joint Flange class 900 | Ring Type joint Flange Class 600 |

| ANSI B16.5 class 300 Ring Type Joint Flange | ANSI 150 Ring Type joint Flange |

| Slip On Ring Type joint flange | High Quality Ring Type joint Flanges |

| Weld Neck Ring Type joint | ANSI Ring Type Joint Flange |

| Ring Type joint Blind Flange | DIN Ring Type joint Flanges |

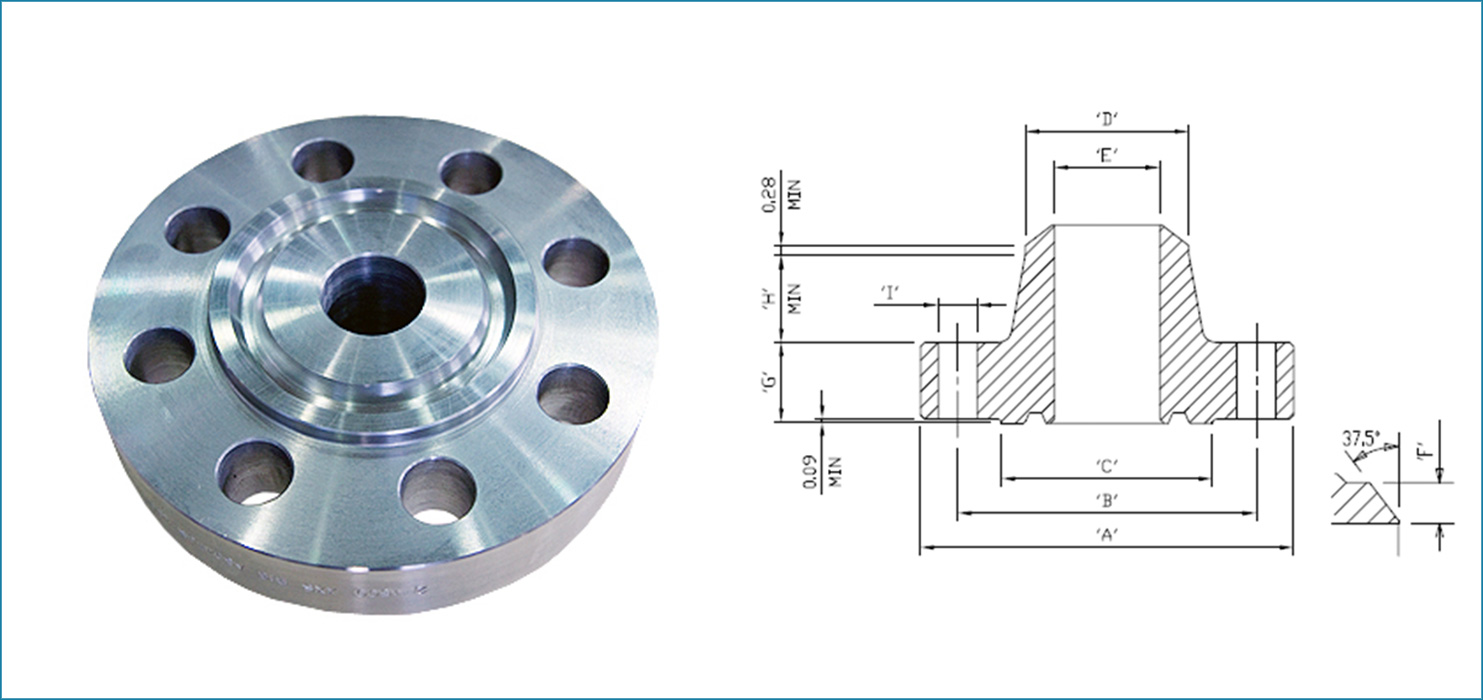

| Nominal Pipe Size | Pitch Diam. of Ring and Groove | Width of Ring | HEIGHT OF RING | Width of Flat on Octagonal Rings | Width of Groove | Depth of Groove | Diameter of Raised Face for Ring Joint or Lapped | Ring Number | Approximate Distande Between Flange of Ring Joints When Ring is Compressed | |

| OVal | Octagonal | |||||||||

| P | A | B | H | C | F | E(L*) | K(Min) | |||

| 1 | 47.6 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 63.5 | R15 | 4.1 |

| 1 1/4 | 57.2 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 73.2 | R17 | 4.1 |

| 1 1/2 | 65.1 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 82.6 | R19 | 4.1 |

| 2 | 82.6 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 101.6 | R22 | 4.1 |

| 2 1/2 | 101.6 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 120.7 | R25 | 4.1 |

| 3 | 114.3 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 133.4 | R29 | 4.1 |

| 3 1/2 | 131.8 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 153.9 | R33 | 4.1 |

| 4 | 149.2 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 171.5 | R36 | 4.1 |

| 5 | 171.5 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 193.5 | R40 | 4.1 |

| 6 | 193.7 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 218.9 | R43 | 4.1 |

| 8 | 247.7 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 273.1 | R48 | 4.1 |

| 10 | 304.8 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 330.2 | R52 | 4.1 |

| 12 | 381 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 406.4 | R56 | 4.1 |

| 14 | 396.9 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 425.5 | R59 | 3 |

| 16 | 454 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 482.6 | R64 | 3 |

| 18 | 517.5 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 546.1 | R68 | 3 |

| 20 | 558.8 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 596.9 | R72 | 3 |

| 24 | 673.1 | 8 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 711.2 | R76 | 3 |

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Width of Ring |

HEIGHT OF RING |

Width of Flat on Octagonal Rings |

Width of Groove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|||

|

OVal |

Octagonal |

|||||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

Class 300 |

Class 400 |

Class 600 |

||

|

1/2 |

34.1 |

6.4 |

11.1 |

9.5 |

4.3 |

7.1 |

5.6 |

50.8 |

R11 |

3.0 |

– |

3.0 |

|

3/4 |

42.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

63.5 |

R13 |

4.1 |

– |

4.1 |

|

1 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

69.9 |

R16 |

4.1 |

– |

4.1 |

|

1 1/4 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

79.5 |

R18 |

4.1 |

– |

4.1 |

|

1 1/2 |

68.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

90.4 |

R20 |

4.1 |

– |

4.1 |

|

2 |

82.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

108.0 |

R23 |

5.6 |

– |

4.8 |

|

2 1/2 |

101.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

127.0 |

R26 |

5.6 |

– |

4.8 |

|

3 |

123.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

146.1 |

R31 |

5.6 |

– |

4.8 |

|

3 1/2 |

131.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

158.8 |

R34 |

5.6 |

– |

4.8 |

|

4 |

149.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

174.8 |

R37 |

5.6 |

5.6 |

4.8 |

|

5 |

181.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

209.6 |

R41 |

5.6 |

5.6 |

4.8 |

|

6 |

211.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

241.3 |

R45 |

5.6 |

5.6 |

4.8 |

|

8 |

269.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

301.8 |

R49 |

5.6 |

5.6 |

4.8 |

|

10 |

323.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

355.6 |

R53 |

5.6 |

5.6 |

4.8 |

|

12 |

381.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

412.8 |

R57 |

5.6 |

5.6 |

4.8 |

|

14 |

419.1 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

457.2 |

R61 |

5.6 |

5.6 |

4.8 |

|

16 |

469.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

508.0 |

R65 |

5.6 |

5.6 |

4.8 |

|

18 |

533.4 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

574.8 |

R69 |

5.6 |

5.6 |

4.8 |

|

20 |

584.2 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

635.0 |

R73 |

5.6 |

5.6 |

4.8 |

|

24 |

692.2 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

749.3 |

R77 |

6.4 |

6.4 |

5.6 |

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Width of Ring |

HEIGHT OF RING |

Width of Flat on Octagonal Rings |

Width of Groove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

3 |

123.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

155.4 |

R31 |

4.1 |

|

4 |

149.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

180.8 |

R37 |

4.1 |

|

5 |

181.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

215.9 |

R41 |

4.1 |

|

6 |

211.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

241.3 |

R45 |

4.1 |

|

8 |

269.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

307.8 |

R49 |

4.1 |

|

10 |

323.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

362.0 |

R53 |

4.1 |

|

12 |

381.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

419.1 |

R57 |

4.1 |

|

14 |

419.1 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

466.9 |

R62 |

4.1 |

|

16 |

469.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

523.7 |

R66 |

4.1 |

|

18 |

533.4 |

19.1 |

25.4 |

23.8 |

11.1 |

19.8 |

12.7 |

593.9 |

R70 |

4.8 |

|

20 |

584.2 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

647.7 |

R74 |

4.8 |

|

24 |

692.2 |

25.4 |

33.4 |

31.8 |

17.3 |

27.0 |

15.9 |

771.7 |

R78 |

5.6 |

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Width of Ring |

HEIGHT OF RING |

Width of Flat on Octagonal Rings |

Width of Groove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1/2 |

39.7 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

60.5 |

R12 |

4.1 |

|

3/4 |

44.5 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

66.8 |

R14 |

4.1 |

|

1 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

71.4 |

R16 |

4.1 |

|

1 1/4 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

81.0 |

R18 |

4.1 |

|

1 1/2 |

68.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

92.2 |

R20 |

4.1 |

|

2 |

95.3 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

124.0 |

R24 |

3.0 |

|

2 1/2 |

108.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

136.7 |

R27 |

3.0 |

|

3 |

136.5 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

168.4 |

R35 |

3.0 |

|

4 |

161.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

193.8 |

R39 |

3.0 |

|

5 |

193.7 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

228.6 |

R44 |

3.0 |

|

6 |

211.2 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

247.7 |

R46 |

3.0 |

|

8 |

269.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

317.5 |

R50 |

4.1 |

|

10 |

323.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

371.6 |

R54 |

4.1 |

|

12 |

381.0 |

22.2 |

28.6 |

27.0 |

14.8 |

23.0 |

14.3 |

438.2 |

R58 |

4.8 |

|

14 |

419.1 |

25.4 |

33.4 |

31.8 |

17.3 |

27.0 |

15.9 |

489.0 |

R64 |

5.6 |

|

16 |

469.9 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

546.1 |

R67 |

7.9 |

|

18 |

533.4 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

612.9 |

R71 |

7.9 |

|

20 |

584.2 |

31.8 |

39.7 |

38.1 |

22.3 |

33.4 |

17.5 |

673.1 |

R75 |

9.7 |

|

24 |

692.2 |

34.9 |

44.5 |

41.3 |

24.8 |

36.5 |

20.6 |

793.8 |

R79 |

11.2 |

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Width of Ring |

HEIGHT OF RING |

Width of Flat on Octagonal Rings |

Width of Groove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1/2 |

42.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

65.0 |

R13 |

4.1 |

|

3/4 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

73.2 |

R16 |

4.1 |

|

1 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

82.6 |

R18 |

4.1 |

|

1 1/4 |

72.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

101.6 |

R21 |

3.0 |

|

1 1/2 |

82.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

114.3 |

R23 |

3.0 |

|

2 |

101.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

133.4 |

R26 |

3.0 |

|

2 1/2 |

111.1 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

149.4 |

R28 |

3.0 |

|

3 |

127.0 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

168.4 |

R32 |

3.0 |

|

4 |

157.2 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

203.2 |

R38 |

4.1 |

|

5 |

190.5 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

241.3 |

R42 |

4.1 |

|

6 |

228.6 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

279.4 |

R47 |

4.1 |

|

8 |

279.4 |

22.2 |

28.6 |

27.0 |

14.8 |

23.0 |

14.3 |

339.9 |

R51 |

4.8 |

|

10 |

342.9 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

425.5 |

R55 |

6.4 |

|

12 |

406.4 |

31.8 |

39.7 |

38.1 |

22.3 |

33.4 |

17.5 |

495.3 |

R60 |

7.9 |

| Flanges pressure rating in psig for RTJ Ring Type Joint Flange ASME |

|||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

ASME B16.5 Ring Type Joint Flanges are known to deliver exceptional performance and are generally developed

for meeting the demands. We oer a broad range of Flat Faced Ring Type Joint Flanges through a worldwide

network of stock-keeping branches. These Ring Type Joint Flange is use in various industries like :

Stainless Steel Ring Type Joint Flanges uses in Oil and Gas Pipeline

Ring Type Joint Raised Face Flanges uses in Chemical Industry

Alloy Steel RTJ Flanges uses in Plumbing

Flat Faced Ring Type Joint Flanges uses in Heating

Ring Type Joint Pipe Flanges uses in Water Supply Systems

ANSI B16.5 Ring Type Joint Forged Flanges uses in Power Plant

RTJ Flanges uses in Paper & Pulp Industry

Ring Type Joint Flange uses in General Purpose Applications

Steel Ring Type Joint Flanges uses in Fabrication Industry

RTJ Flange uses in Food Processing Industry

Ring Type Joint Flanges uses in Structural Pipe

| MIDDLE EAST | AFRICA | NORTH AMERICA | EUROPE | ASIA | SOUTH AMERICA |

| Saudi Arabia | Nigeria | Usa | Russia | India | Argentina |

| Iran | Algeria | Canada | Norway | Singapore | Bolivia |

| Iraq | Angola | Mexico | Germany | Malaysia | Brazil |

| Uae | South Africa | Panama | France | Indonesia | Chile |

| Qatar | Libya | Costa Rica | Italy | Thailand | Venezuela |

| Bahrain | Egypt | Puerto Rica | Uk | Vietnam | Colombia |

| Oman | Sudan | Trinidad And Tobago | Spain | South Korea | Ecuador |

| Kuwait | Equatorial Guinea | Jamaica | Ukraine | Japan | Guyana |

| Turkey | The Republic Of Congo | Bahamas | Netherland | Sri Lanka | Paraguay |

| Yemen | Gabon | Denmark | Belgium | Maldives | Uruguay |

| Syria | Greece | Bangladesh | |||

| Jordan | Czech Republic | Mayanmar | |||

| Cyprus | Portugal | Taiwan | |||

| Hungary | Cambodia | ||||

| Albania | |||||

| Austria | |||||

| Switzerland | |||||

| Slovakia | |||||

| Finland | |||||

| Ireland | |||||

| Croatia | |||||

| Slovenia | |||||

| Malta |

Phone+86 151 277 20688

Phone+86 151 277 20688 Tel+86 151 277 20688

Tel+86 151 277 20688 E-mailsales@hgffgroup.com

E-mailsales@hgffgroup.com