+86 151 277 20688

+86 151 277 20688

sales@hgffgroup.com

sales@hgffgroup.com

We, HGFF Group Co.,Ltd. have a quality control system that is wholesome and effective: we have assessed a range of products over three decades, none of them leaving our premises with a defect. Besides, we

We, HGFF Group Co.,Ltd. have a quality control system that is wholesome and effective: we have assessed a range of products over three decades, none of them leaving our premises with a defect. Besides, we

are third party inspectors for agencies engaging in completely diverse businesses. Our Carbon Steel Socketweld Outlets made in accordance with ASTM A105 specification;a 90° branch or an outlet is formed which is ductile yet strong. Recognized as socket weld fittings, Duplex Steel Socketweld Outlets are resistive to chloride stress corrosion cracking, the nitrogen enhanced steel warding other side-effects of minor corroding activities as well. These Stainless Steel Socketweld Outlets serve the pulp mills. We are suppliers of Titanium Socketweld Outlets that grant full media flow due to their carefully designed bodies that give exhibition for welding. We are exporters of class 3000, 6000 and 9000 Inconel ASME B16.11 Socketweld Outlets,fruitful in connecting small-bore piping to larger size pipe runs

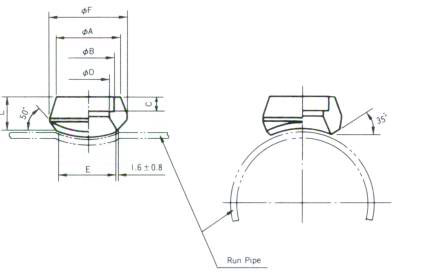

Dimensions : ASME 16.11, MSS SP-97, BS 3799

Size : 1/2″ to 24″

Pressure Class : 3000 LBS, 6000 LBS, 9000 LBS

Form : Socket weld Outlets, Socketweld Outlets.

Material & Grades of Socketweld Outlets :

Stainless Steel Socketweld Outlets :

ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L.

Duplex & Super Duplex Steel Socketweld Outlets :

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Carbon Steel Socketweld Outlets :

ASTMA 105 / A694 / Gr. F42 / 46 / 52 / 56 / 60 / 65 / 70.

Low Temperature Carbon Steel Socketweld Outlets :

A350 LF3 / A350 LF2.

Alloy Steel Socketweld Outlets :

ASTM / ASME A / SA 182 F1 / F5 / F9 / F11 / F22 / F91.

Nickel Alloy Socketweld Outlets :

ASTM / ASME SB 564 / 160 / 472 – UNS 10276 (HASTELLOY C276), UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201),

UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601

(INCONEL 601), UNS 6625 (INCONEL 625).

Copper Nickel Socketweld Outlets :

ASTM / ASME SB 61 / 62 / 151 / 152 – C70600 (CU-NI-90/10 Cupro Nickel Outlets), C71500 (CU-NI-70/30 Copper

Nickel Outlets)

Olets Branch Connection – Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

|---|---|---|---|

| 3000 Lbs | 6000 Lbs | ||

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1″ | 13 | 22 | 29 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

General notes:

ASME B16.11 Socketweld Outlets are known to deliver exceptional performance and are generally developed for

meeting the demands. We offer a broad range of Socketweld Outlets through a worldwide network of stock-keeping branches. These Socketweld Outlets is used in various industries like :

Stainless Steel Socketweld Outlets uses in Oil and Gas Pipeline

Socketweld Outlets uses in Chemical Industry

Alloy Steel Socketweld Outlets uses in Plumbing

Socketweld Outlets uses in Heating

SS Socketweld Outlets uses in Water Supply Systems

ASME B16.11 Socketweld Outlets uses in Power Plant

CS Socketweld Outlets in Paper & Pulp Industry

Alloy 20 Socketweld Outlets uses in General Purpose Applications

Carbon Steel Socketweld Outlets uses in Fabrication Industry

Titanium Socketweld Outlets uses in Food Processing Industry

Buttweld 45° Short Radius Elbow uses in Structural Pipe

|

|

|

Phone+86 151 277 20688

Phone+86 151 277 20688 Tel+86 151 277 20688

Tel+86 151 277 20688 E-mailsales@hgffgroup.com

E-mailsales@hgffgroup.com