General notes:

- Dimensions are in millimeters unless otherwise indicated.

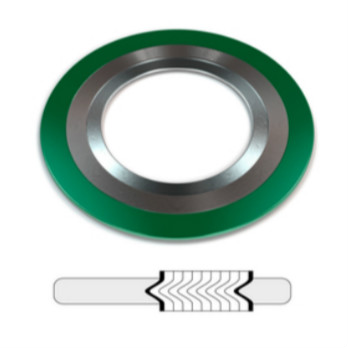

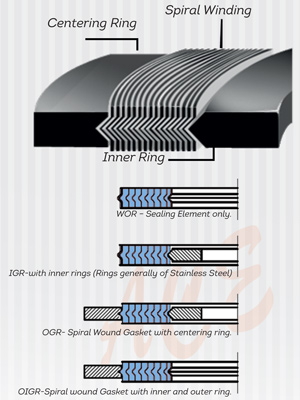

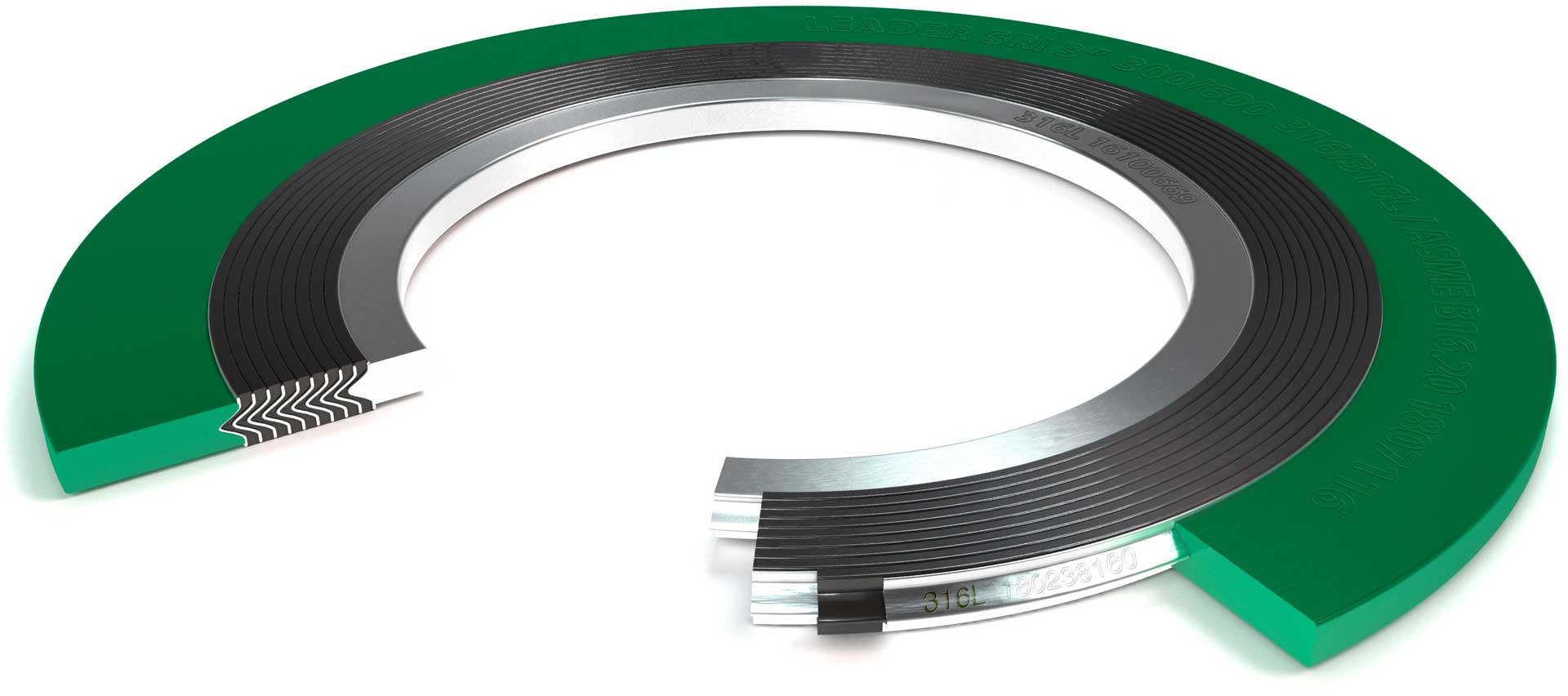

- Image shows a Spiral Wound gasket with Inner – and Outer ring.

- d1 = Inside diameter when Inner ring is used.

- d2 = Inside diameter sealing element when no Inner ring is used.

- d3 = Outside diameter of sealing element.

- d4 = Outside diameter of Outer ring.

- The thickness of the inner and outer ring: 2.97 mm – 3.33 mm.

- Thickness sealing element: 4.45 mm.

- Tolerance Outside diameter for NPS 1/2 through NPS 8 is ± 0.8 mm; for NPS 10 trough NPS 24 tolerance is + 1.5 mm – 0.8 mm.

- ASME B16.20 does not cover class 400 flanges up to NPS 3 and class 900 flanges up to NPS 2.1/2.

- There is no class 400 flanges NPS 1/2 thru NPS 3 (use Class 600), class 900 flanges NPS 1/2 thru NPS 2.1/2 (use Class 1500), or class 2500 flanges NPS 14 or larger.

- The inner ring inside diameters shown for NPS 1.1/4 thru 2.1/2 in class 1500 and 2500 will produce inner ring widths of 0.12 inches, a practical minimum for production purposes.

- ASME B16.20 which covers spiral wound gaskets requires the use of solid metal inner rings in: Pressure Class 900, nominal pipe sizes 24 and larger, Pressure Class 1500 from nominal pipe sizes 12 and larger, Pressure Class 2500 from nominal pipe sizes 4 and larger and all PTFE filled gaskets.

HGFF Group Co.,Ltd is a Supplier of custom spiral wound gaskets. HGFF engineered spiral wound gaskets are ideal for applications that demand a gasket with the highest-quality flexibility and recovery to maintain a seal even in conditions characterized by fluctuating temperature and pressure.

HGFF Group Co.,Ltd is a Supplier of custom spiral wound gaskets. HGFF engineered spiral wound gaskets are ideal for applications that demand a gasket with the highest-quality flexibility and recovery to maintain a seal even in conditions characterized by fluctuating temperature and pressure.

MESSAGE

MESSAGE